Part 6: Cracked or non-cracked concrete?

Concrete is used in construction both unreinforced and reinforced. The type of steel bar most commonly used for reinforcing reinforced concreteis known as rebar. Concrete endures compression well but cracks easily when subjected to traction, while steel endures traction well.

In practice, a concrete structure always has cracks caused by internal and external conditions, stresses and loads, but they are not considered defects when they are small. Correctly designed concrete reinforcement limits the spreading of cracks and transfers the traction forces across the cracks, thereby preventing the cracks from expanding into defects which would compromise the durability of the structure.

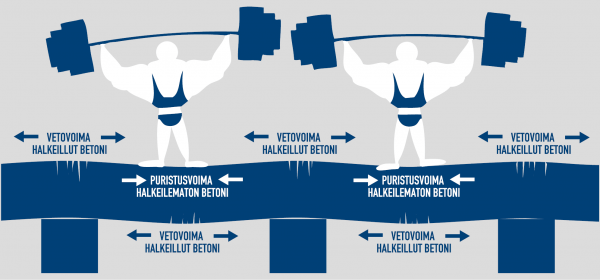

For example, when a concrete slab between two support columns is stressed from the above, the lower edge of the slab stretches and the top edge is compressed due to the effect of its own weight and the weight above the slab. The top edge of the slab is therefore stressed by compression force and the lower edge by traction force. The concrete at the top surface of the slab endures the compression force, but steel must be added to the lower edge to receive the traction forces to prevent the cracks in the structure from growing too large.

ONLY USE APPROVED FIXINGS IN CRACKED CONCRETE!

When fixings are made into the cracked section of concrete, it should be noted that the cracks damage the load-carrying capacity of the fixing base and thereby have effects on the load-carrying capacity of the fixings. Sormat’s product range includes several fixings approved for cracked concrete, such as through bolts and the S-UF® and S-UP® frame plugs. The suitability of a fixing for cracked concrete is mentioned separately in the product specifications.

Remember: European Technical Assessment (ETA) options 1–6 are for cracked and non-cracked concrete, options 7–12 only for non-cracked. Be particularly careful with fixings into the ceiling and generally overhead!

Remember: European Technical Assessment (ETA) options 1–6 are for cracked and non-cracked concrete, options 7–12 only for non-cracked. Be particularly careful with fixings into the ceiling and generally overhead!