Part 9: A reliable fixing requires a drill hole of the right size!

THE BUILDING MATERIAL FUNCTIONING AS THE INSTALLATION BASE DETERMINES THE DRILLING TECHNIQUE TO USE.

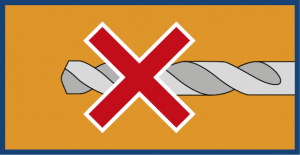

No drilling

The fixing is installed by hammering or screwing it directly into the porous building material.

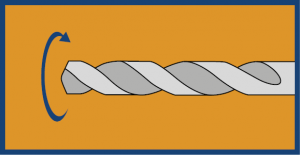

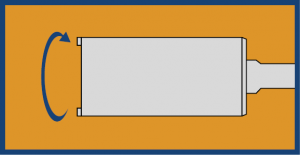

Rotary drilling

Non-percussion drilling based on the rotating movement of the drill bit with a regular screwdriver into materials with a weak compression strength, such as building boards.

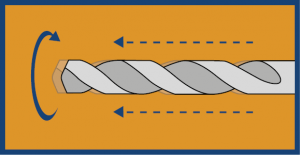

Percussion drilling

The drilling technique is based on the rotating movement of the drill bit and rapid but light impacts of the percussion action. Percussion drilling is used for solid compact building materials when the diameter of the drill bit is under 20 mm. Drilling into bricks can be begun without the hammering function, but if no hole begins to emerge, percussion drilling is started.

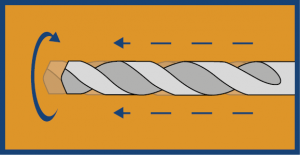

Hammer drilling

The hammering technique is based on the rotating movement of the drill bit and the slow heavy impacts of the hammering action. Used for solid compact building materials.

Diamond drilling

Rotary drilling with a diamond drill bit and without hammering action is used when drilling drill holes with a particularly large diameter and

Remember in particular: To clean the drill hole carefully with a brush and vacuum cleaner/air pump To drill a sufficient deep drill hole at once, often the suitable depth is installation depth hnom + 10 mm Use of a badly worn drill bit is a safety risk and makes the installation work more difficult!

Remember in particular: To clean the drill hole carefully with a brush and vacuum cleaner/air pump To drill a sufficient deep drill hole at once, often the suitable depth is installation depth hnom + 10 mm Use of a badly worn drill bit is a safety risk and makes the installation work more difficult!